|

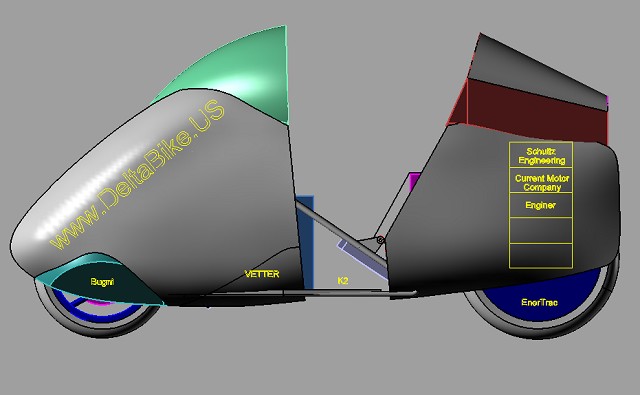

Schultz Engineering, LLC 2011 Concept Vehicle |

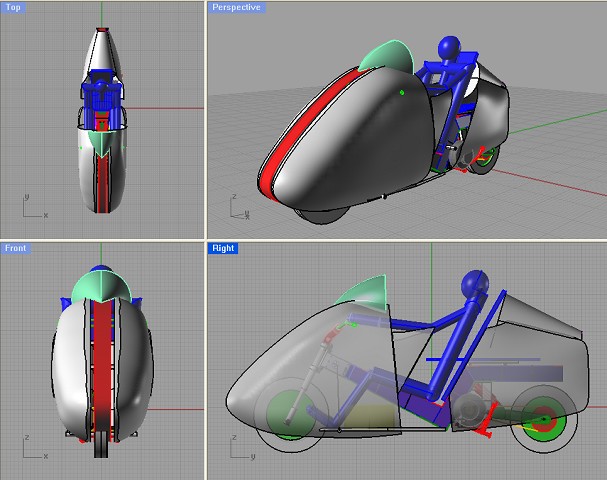

DELTA-11tm - Developing the Worlds Most Efficient, Practical Electric Motorcycle DELTA-11tm is an all-electric motorcycle designed for High Efficiency. As part of the Delta-Bike modular vehicle line-up being developed by Schultz Engineering, LLC, the Delta-11 can be upgraded from the base model, by installing different motors, batteries and bodies. A unique feature of the vehicle is a seat that pivots allowing the rider to lower into the vehicle for better aerodynamics and comfort. The DeltaBikes will be marketed and sold by DeltaBike USA. For information about purchasing a production DeltaBike, visit www.DeltaBike.US. |

|

Vehicle Efficiency High Efficiency is the "secret sauce" for the D-11. The Delta-11 concept vehicle will be dramatically more efficient than other motorcycles currently on the market. Higher Efficiency is achieved by carefully combining higher motor efficiency, better aerodynamics, less frontal and surface area, higher efficiency batteries, lower rolling resistance, and less weight. |

|

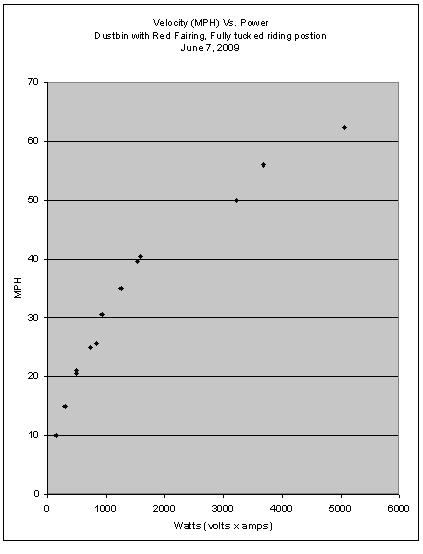

Vetter Fuel Economy Challenge 2011 Announced - January 2011 Craig Vetter announced that he is planning two Vetter Fuel Economy Challenges to take place this year. The first will be in at the Quail Gathering in California (May 13, 2011). The second challenge will be at AMA Vintage days in Ohio (July 22, 2011). Each challenge includes a 100-mile ride on public roadways at posted speed limits up to 65mph. The winner will be the vehicle that can carry 4 bags of groceries while consuming less fuel in dollars and cents than Craig (who will be riding his Yellow Helix Streamliner). See full listing of rules at Vetter Fuel Economy Challenge We are planning to ride in both rides, because it is an opportunity to show that electric vehicles are back in the race (after 100 years on the sidelines). The picture and chart below reflects the best Schultz Engineering has achieved with a conventional design motorcycle and a dustbin fairing. This motorcycle would require a 12 kWh battery to complete the Vetter Challenge. But this motorcycle only had room for a 2 kWh battery and 1 bag of grocery's! So, we're designing a better vehicle. One that has better aerodynamics, less rolling resistance, more cargo space, and a more efficient drive system.   |

|

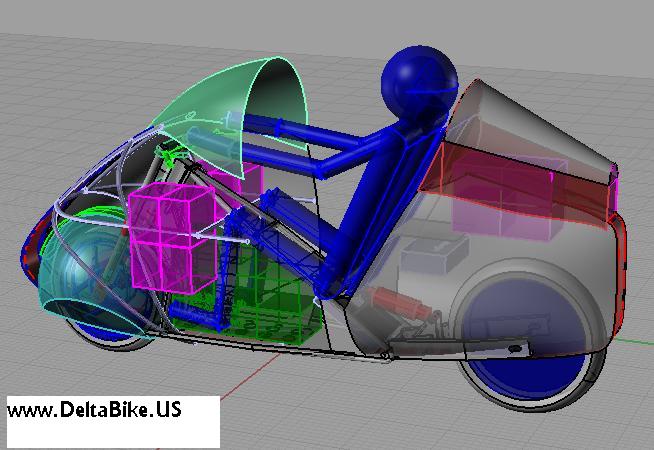

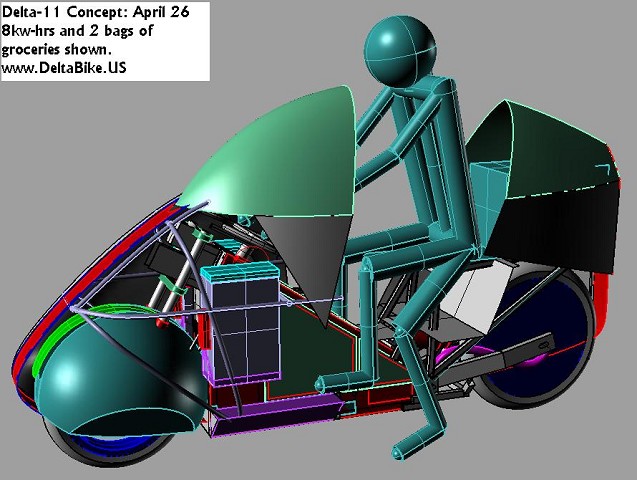

Four Bags of Groceries - February 2011 A practical commuter vehicle must be able to carry cargo. We are designing our motorcycle to safely carry 4 bags of groceries. You can see two grocery bags up front and two in the rear in this Ghost-view rendering (grocery bags in pink).  |

|

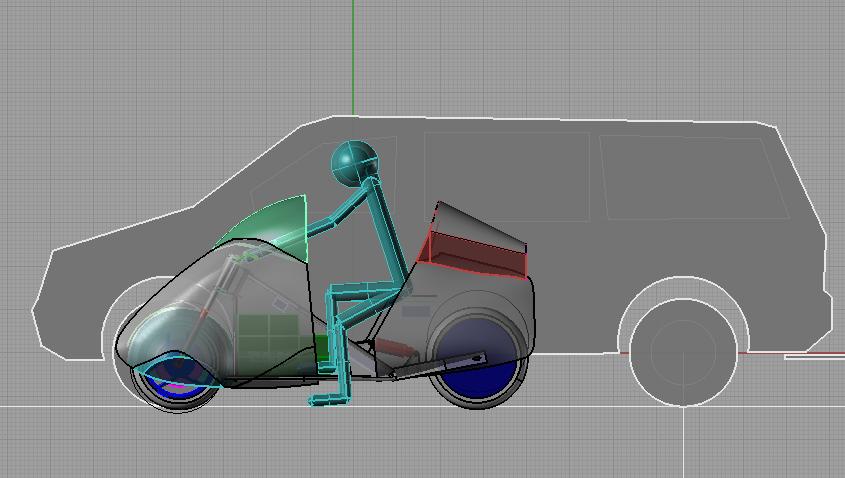

Safety In Traffic - March 2011 A motorcyclist must be able to see and be seen. The Delta-11 has two riding positions. The lower riding position is for the open road. The upright riding position (shown below) is for riding in traffic where visability is a requirement.  |

|

Sponsers - March 2011 We are are proud of our sponsers and will be displaying their corporate logos on our Vetter Fuel Challenge bike. More to come as we get closer to paint.  |

|

High Efficiency Drive System - March 1, 2011 We're using the best motorcycle hub motor available today. It's a 40 hp hub motor from Enertrac. Compared to other options, this motor offers more power, space savings, better efficiency, lower maintenance and less noise.  |

|

Milestone Day - All Major Purchased Components Have Arrived - March 31, 2011 The batteries and hub motor arrived today. So, now we have all major components in hand. As usual, the weight of each component is shown in the picture. This bike will be heavier because it will have a top speed approaching 80mph and a range of 100 miles! With actual parts in hand, they can be measured, the design finalized and the bike built. Hang on, this should be an exciting month!  |

|

Tweaking for Comfort - April 5, 2011 There is no better way to optimize a design for comfort than to sit in it. With Computer Aided Design (CAD) we can make all the parts fit, but to make it comfortable, people need to sit in it and figure out what feels good. Here is a picture of a full-scale Delta-11 seating model being built-up.  |

|

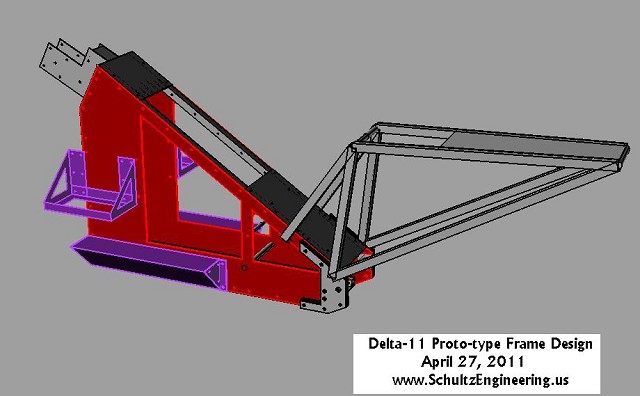

Details - April 26, 2011 With just 12 days left before the bike must leave for California, the frame design is released to start building!   |

|

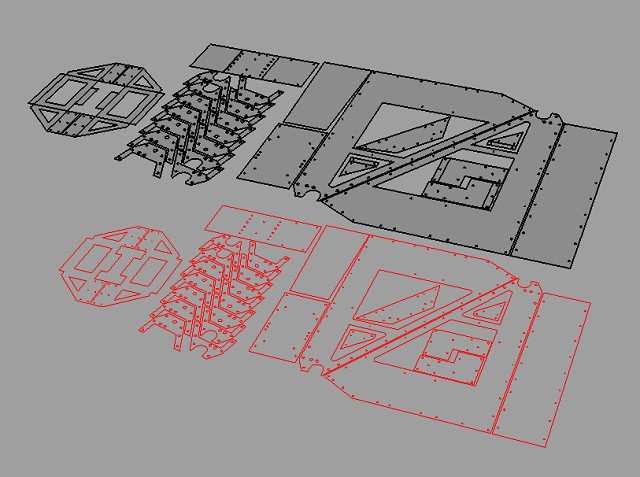

Waterjet Cutting - April 27, 2011 All flat work will be cut out of aluminum sheet via Waterjet cutting. The picture below shows the actual parts and the red lines are the waterjet cutting path. The entire frame will be bolted together. In theory, no welds will be required, but some may be added as needed after the frame is bolted together. Due to the precision of the hole locations, the frame can be assembled and welded without the construction of a welding jig.  |

|

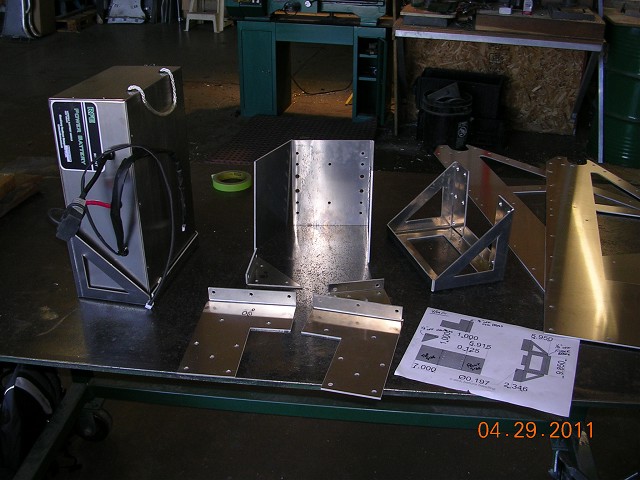

Waterjet Cutting - April 29, 2011 Parts came back from waterjet cutting and were bent.   |

|

Drilling and Tapping Frame Rails - May 1, 2011 We started drilling and tapping the old fashioned way, but this turned out to be a lot of work and we were worried about loosing the hole locations. So, after a few holes, we threw the rails on the CNC and drilled and tapped them faster and with better precision.  |

|

Making Progress - May 4, 2011 Frame pieces are starting to come together...  |

|

California Trip Cancelled - May 5, 2011 Due to the bike not being finished, we have cancelled our trip to California to participate in the Quail Gathering. This is a big disappointment for us, and we had to contact our sponsers today and let them know. |

|

Headtube Connection Redesign - May 5-9, 2011 Once the Quail trip was cancelled, the first order of business was to redesign the sheet metal headtube connector with a more precise and stronger design out of billet. The finished assembly weighs more than we'd like, but it can be redesigned for lightness later. Right now, the extra 6 pounds is well worth the safety when going down the road at 80mph!   |

|

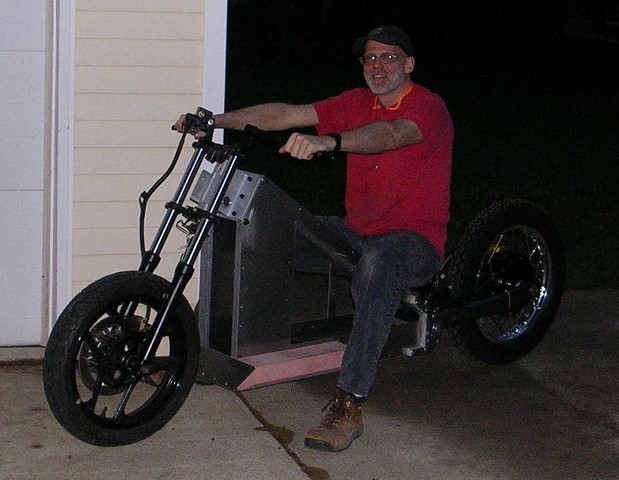

First Roll Test is Successful - May 9, 2011 We did it. This proto-type frame is completely bolted together. Not a single weld was used! It's great to be being rolling on two wheels!  |

|

Focus - May 13, 2011 May 13th. The first Vetter Fuel Economy Challenge is taking place in California today, but we're still building. While working on building and trying to get ready for events, it's easy to forget what we are trying to accomplish. The R&D goals of the Delta-11 concept bike are as follow:

|

|

Battery's Mounted - May 14, 2011 All batteries are securely mounted, all electricals are roughly placed. Ready to start wiring.  |

|

Wiring Final Connections - May 20, 2011 Today is the day to make that final connection...The wiring for the Enertrac hub motor was very easy as all the components came with snap together terminals.  |

|

First Road Test - Seems Like Riding a Magic Carpet - May 22, 2011 This Hub Motor is awesome! Very torquey, and so much quieter than a chain driven bike...seems like how riding a magic carpet would be. Everything checked out great. Bike handles well, no shimmey's, very stable.  Here's a You Tube Video of pieces of the test. http://www.youtube.com/watch?v=-6a1LRRYZXA |

The Prototype as of May 22, 2011  |

|

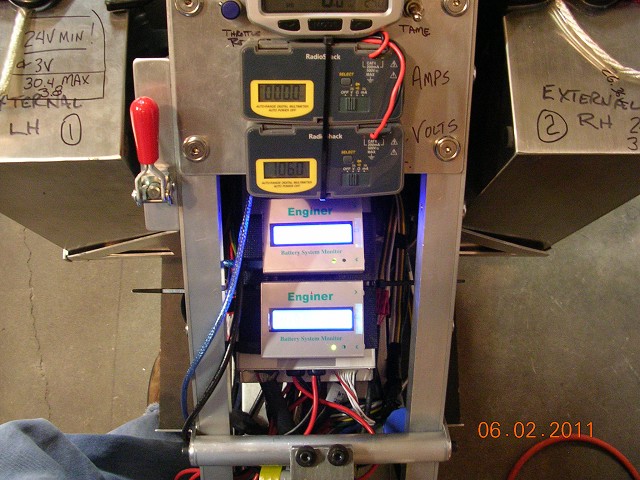

The FUN begins May 24, 2011 We've got the bike inspected, titled, licensed and insured. It now has a speedometer, volt and amp meters, and regenerative braking. Now we can start experimenting to make it perform better and better. The electric bike is the ultimate platform for doing experiments because it is so easy to measure improvement - make a change, take a test drive - at a given speed, what does the amp meter say? Is this better or worse than before the change? August 20, 2011 Note: Speedometer was calibrated 7.6 percent off, so maximum speed shown here was actually 63mph NOT 68.1mph as speedometer indicates.  |

|

Initial Numbers: May 24, 2011 Maximum Speed without Body: 63mph Electricity Cost Per Mile: $.017 Watt-Hours Per Mile: 144 Gasoline Equivalent ($3.50/Gallon): 200mpg+

Data:

At 63mph, current draw was 100amps and voltage was 105 (that is 11,550 watts or about 15.5 Hp). It took 1,800 watts from the wall to recharge the bike after riding 12.5 miles at 50mph. Observations: 1. With the controller set at a maximum of 80amp output (which is the maximum continuous current recommended for our prototype battery pack), the bike still has nice acceleration (thanks to 2-speed hub motor) and a top speed of 56mph. 2. Using the regenerative braking to slow down feels good. It's rewarding to feel the bike being slowed down by regenerative braking because you know you are charging your batteries with normally wasted energy. You can actually "see" the electricity flowing back into the batteries on the guages (voltage increases and the amp meter reads negative numbers). |

|

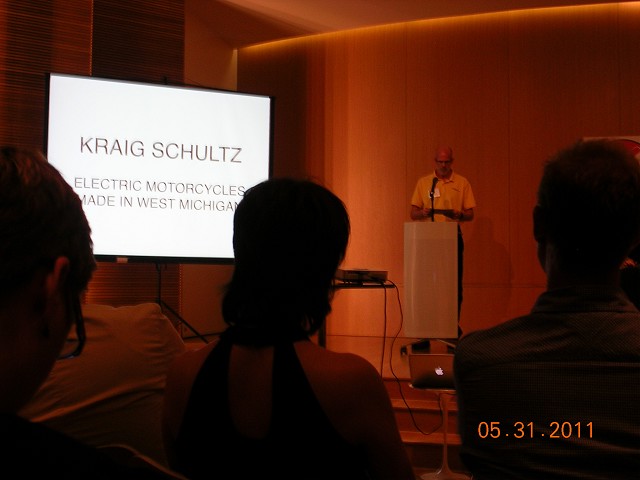

5x5 Night Event - May 31, 2011 Kraig participated in a local inventors competition called 5x5 night. He didn't "win" the $5,000 cash purse, but he got to share our mission and meet a lot of people. You can see it at http://www.ustream.tv/recorded/15083701. Kraig was the last presenter of the five. His presentation starts at 25:15 in this Streaming Video. Tony Helmholdt rode his electric motorcycle to the event from Ada to attend the event.  |

|

BMS Installed and Being Tested - June 2, 2011 BMS units finally arrived and have been installed. Road testing has been going on to learn about the batteries and how they respond to use and recharging. The Enertrac hub motor is a joy to drive. The two speed functionality is really great. The bikes max speed in "1st gear" is 37mph. Initial rides between 9-22 miles in length yield the following observations: Energy Consumption (without body) 28mph = 89 Wh/Mile 37mph = 102 Wh/Mile Current draw on flat and steady (without body) Crouched Position at 37mph = (25 amps at 105volts = 2,600 watts) Upright Riding Position at 37mph = (30 amps x 105volts = 3,150 watts) The batteries and BMS units are working good.  |

|

Pictures Before Stage 2 - June 4, 2011 Stage 2 is to add the Streamlined body work. We really like the bobber style, and would like to ride it more, but we need to get a body on this thing. So here are a few pictures before we tear into the changes.   |

|

Phase 2 - Adding an Aerodynamic Body It's time for a page 2 in the build of this bike. Click here (www.schultzengineering.us/delta-11-2.htm) to see the installation and testing of the Rifle Vetter Fairing.  NEXT PAGE |

|

Inventing a better tomorrow today... Copyright 2010-2011, Schultz Engineering, LLC |