|

CHAPTER 9 - Air Venture 2010 |

|

AIR VENTURE 2010 Oshkosh, WI July 24-August 1, 2010 Comments about the event by Kraig Schultz, founder of Schultz Engineering, LLC (www.schultzengineering.us) This was my first Oshkosh Air Venture and all I can say is "Wow!". It was way more than I expected it to be. Daily Air shows, Hands on Workshops, thousands of Airplanes of all types (war birds, antiques, new planes, home builts, kit planes, general aviation, experimentals, ultra-lights, gliders, etc.), aircraft suppliers and factory airplanes to see. Used parts, the EAA musuem, clean camping facilities, presentations by industry experts and celebrities. I attended Airventure from 3pm Wednesday to 10am Saturday. I did not have enough time to see everything I wanted to see. I attended 1.5 days of seminars/workshops and this left me way too little time just to take in the aircraft and air shows and even all the workshops I would have like to have attended. I took over 350 pictures and the pictures below are just a random sampling of planes related to my interest in how to put a skin on my electric motorcycles. I went to AirVenture 2010 for the following reasons: -To learn about air-craft construction, specifically the fabric covering techniques -To learn about air-craft structural techniques -To see if Oshkosh is a good sales venue for the Delta-11/Delta-12 Electric Motorcycle Kit -To learn about Kit Airplanes -To see an airshow Mission Accomplished!!! Unexpected bonus = The electric Airplane Symposium all day Friday- to hear and learn from industry experts on the status of electric transporation - airplanes and automobiles. |

There was a tent set-up called the Aeroplane Factory. In there, they were building and re-doing airplanes. Here are some pictures of a vintage plane having fabric installed while you watch.

Some notes on the plane by Jim Self who is shown in the pictures using a standard clothing iron to shrink the fabric: "The plane belongs to the EAA and will reside at Pioneer Airport as a museum display when it's finished. It won the 1928 transcontinental airplane race, so it's at least that old. I think it was piloted by John Livingston during the time frame. It's a Waco Taperwing. We covered the wings and control surfaces last year so they're getting close to being able to put it all back together.  |

I attended a Poly Fiber seminar on Fabric systems. I learned about the major fabric systems and their history, and then went to the hands on portion where I got to wrap this frame under expert step by step instruction from Lynn Zaro. The Poly Fiber system is the best vintage system (solvent borne) out there using vinyl coatings for each step (therefore not requiring a fresh air breather). The Stewart system is a newcomer and being waterborne seems like it might be the way to go for me. Also, the Steward system glueing is much more forgiving as the fabric can be positioned at your leisure on the glue unlike the MEK glue that dries so fast it's hard to get the fabric positioned.

The Fabric is polyester that hasn't been shrunk yet. It will shrink 5 percent at 250 degrees F and 10 percent at 350 degress. at 426 degrees the fabric melts. What this means is you can take a standard iron and set it at a temperature that will give you the shrink you want and you can hold it right on the fabric and get an exact shrink without worrying about melting the fabric. You can shrink the fabric as needed before and during glueing to make it go around corners and arcs without wrinkling. Great stuff, and really easy to work with.  Here is an airplane wing with the fabric on after the foundation layer of evidently the Poly Fiber system. A brush was used to coat the fabric forcing the base coat to soak through the fabric and encapsulate the fabric front and back side. Per Jim Self, not a wing but "Actually the right elevator from the EAAs B-17 Aluminum Overcast. Over the last couple of years we've recovered a complete set of control surfaces they've slowly installed."  |

Wing ribs were originally made of wood and constructed using assembly jig like this.

Now, you can purchase wing ribs made of aluminum. This manufacturer had an awesomely strong aluminum extrusion based rib.  |

At the EAA Air Museum (free of charge to Oshkosh Attenders), I spent several hours wandering around. They had a great selection of items. This plane was all sectioned out to show vintage airplane construction. You can see clearly how the rib stichcting on the wings goes all the way from the top side of the wing to the bottom of the wing and zig-zags back and forth. This holds the fabric via a mechanical bond to the surface of the rib and adds a lot of strength to the rib itself. Fabric can also be screwed or riveted to the rib.

Here is a Be Lite Airplane with carbon fiber wings. The entire plane weighs less than 254 lbs! making it an ultralight with the look and feel of a real airplane. http://www.beliteaircraft.com/  I was intrigued by several planes I saw that had nylon fabric covering (non-shrunk, non coated). Polyester fabric is shrunk and along with the coatings becomes fairly rigid and quite tough. With coatings, the fabric coating can last 20-25 years out in the weather. Unprotected nylon would have a much shorter life but have the distinct advantage of lower cost and being very easy for the end user to swap out colors/designs frequently.   There were hundreds of Utlralights of all types with plastic or composite nosecones and various degrees of fabric and plexiglas...  |

Stressed skin aluminum aircraft.

An ultra-light (254 pounds) kit plane. http://www.flyhummel.com/ultra_cruiser.htm  The Sonnex: A high performance, easy to build, affordable aluminum kit plane - I will benchmark these guys for how they do kit planes as my friend is planning to build one. http://www.sonexaircraft.com/   Rick Gray's F1 Rocket - Such a beautiful homebuilt plane that I had to include the picture. All aluminum riveted construction.  The BD-5 at the EAA musuem. Stressed aluminum skin, but neat little shape.  |

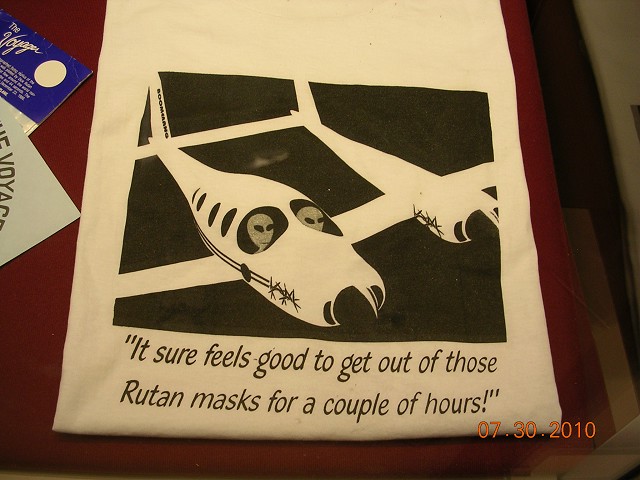

Some composite airplanes (there is no mistaking a Dick Rutan airplane).   Yes, that is a flying concept car. Worth the compromises? A neat design challenge and an interesting study in design synergy. Seems odd to me, that it would turn out looking like a traditional car...  |

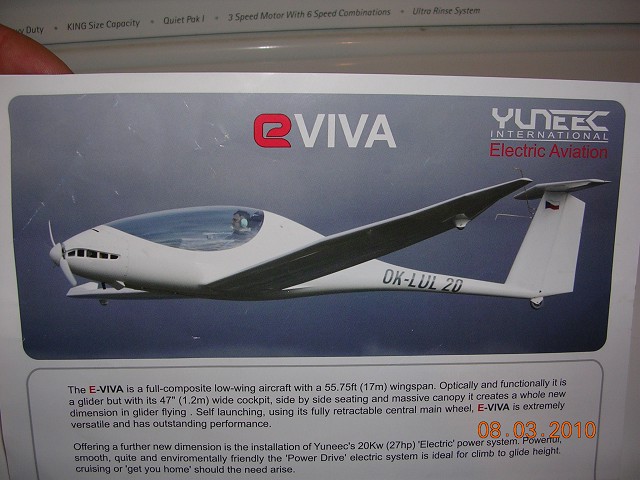

Larry Mauro, designer of the popular UFM Easy Riser, designed and built an entirely solar powered glider. On April 29, 1979 the Solar Riser made the world’s first official flight in a solar powered, fully controlled, man carrying flying machine. The ultralight reached an altitude of approximately 40 feet and flew for about a half a mile before landing gently. From http://www.airventuremuseum.org/collection/aircraft/UFM-Mauro%20Solar%20Riser.asp  Electric self-launching gliders are now a commercial reality. An electric powered glider flew at the air show putting asides all doubts that electric flight is here today! As battery's get better, we will see more and more electric airplanes. The concensus of all the speakers at the Electric Airplane symposium on Friday was that electric airplanes are feasible but not yet practical due to the high cost and low energy density of batteries.  |

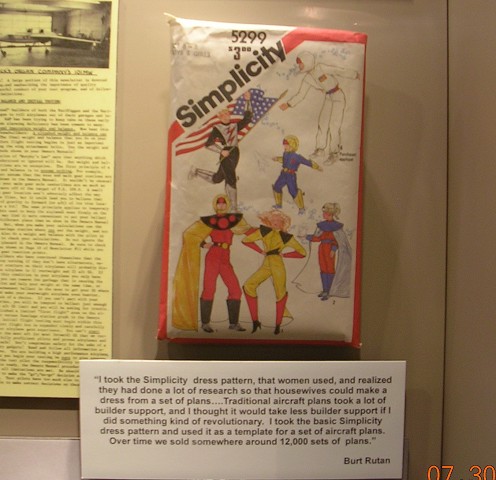

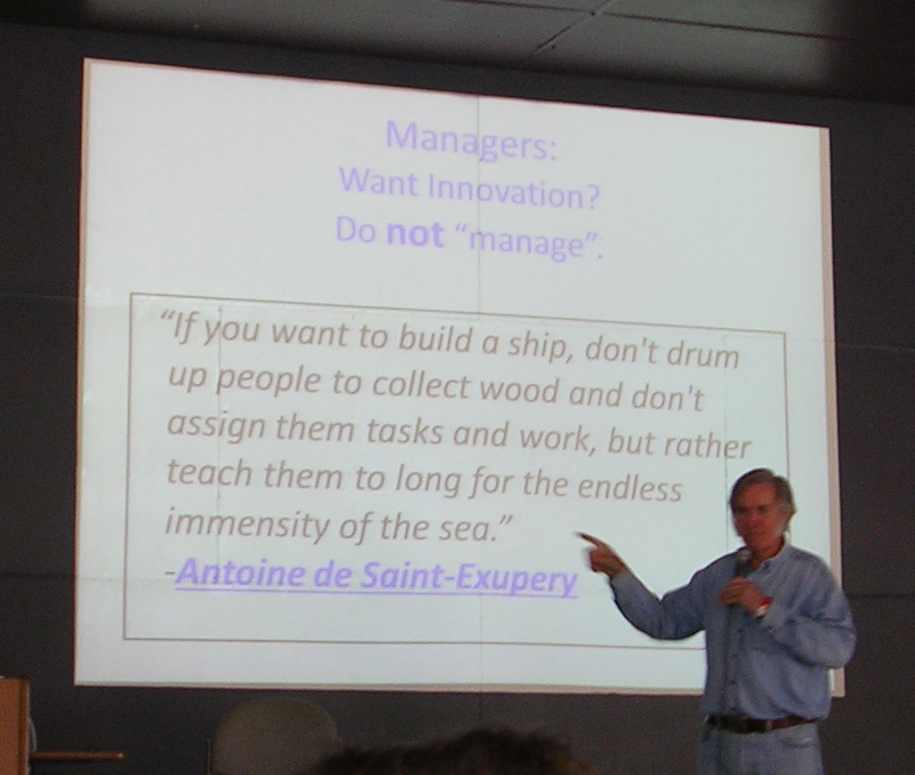

I had the great privilage to attend several talks by Dick and Burt Rutan at Airventure. These guys are very inspirational. Their contribution to Aeronautics cannot be measured. Much of their success can be attributed to their upbringing. Dick said his mother would often tell him, "If you can dream it, you can do it. The only way you can fail, is if you quit."   Burt said we should encourage our kids to think about that they want to see happen in their lifetime and then to think about what they can do to make it happen. He said we need to give our kids an exciting vision of the future that gives our kids something to dream about. He said nothing is more fun than being able to do something that you once thought was impossible. Both Rutan's encouraged us to experiment and to try the impossible, to expect failure, but to never give up. They both reminded us of the incredible freedom we have to experiment in this country and that we should work to protect this freedom. Burt Rutan making a point...  |

Key Take Aways: Airplane builders are my kind of people. 2011 Go for the entire week! Ride one or two Delta's from home to Oshkosh as proof of concept. Having an aircraft styled body would be a great sales linkage. The lowest cost way to "sell" my electric vehicle would be to camp at Camp Scholler in a strategic location (campsites are first come, first serve, so I might get there even a week ahead of time to get a great site). Bring two or three Delta's to Oshkosh. Have a Delta-11 with body and a Delta-12 with body and a bare Delta-12. Plan to drive the Delta around the grounds as much as I want. Let the bodywork and advertising painted on the body "pre-sell" the vehicle. Park one vehicle in the parking lot by the entrance/exit. Have a moped and a motorcycle version - have Maggie drive the moped version around. Have a map painted on the body - Oshkosh 2011 or bust! Here is the way I see aircraft evolution after spending time at Oshkosh... Generation 1 - Fabric over wood Generation 2 - Stressed Aluminum Skin Generation 3 - Composites: Fiberglass and Carbon Fiber Generation 4 - Electric Powered Flight |

|

(Next Chapter - Building Delta-11 Prototype) |

|

Inventing a better tomorrow today... Copyright 2010, Schultz Engineering, LLC |