|

CHAPTER 2 - BURNING RUBBER AND SILICON |

June 18, 2007. Registered as a Moped in Michigan! |

July 12, 2007. 38 amp-hour batteries arrived. $25 for each battery at www.batterymart.com |

July 22, 2007. Wider battery box. |

July 22, 2007. 38 amp-hour batteries installed. The larger batteries added about 60 pounds to the total vehicle weight. |

The 38amp-hour batteries added about 7 inches to width of bike making my narrow highway pegs unusable. Notice the butt switch. This is a DPST switch that bypasses the twist grip throttle potenionmeter to a resistor of fixed resistance. It has velcro under it and is normally stored on top of the batteries, but can be positioned under my right or left leg. This allows for several great things: |

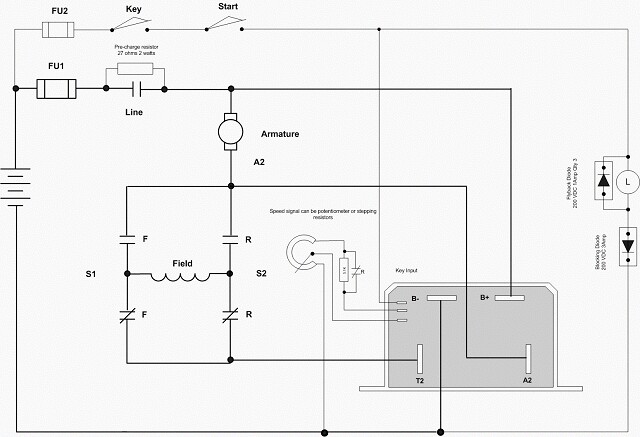

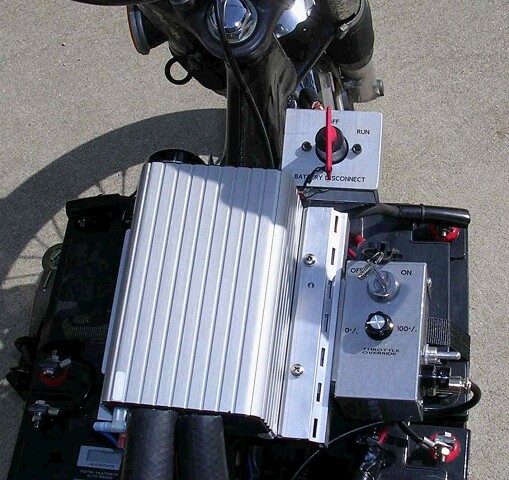

September 8, 2007: CONTROLLER BLEW UP TODAY (510 miles on Controller). The Picture above shows no user serviceable parts inside the controller. But, you can see that it had gotten hot enough inside to melt the plastic off three capacitors sticking out of the epoxy sealant. On September 2, Labor Day weekend, we went up to Chicago for the day and I took my bike on a 1.5 hour city ride (straight through the downtown, from the Blackstone Hotel at the south end of the city to Lincoln Park at the north end via Michigan Avenue and Rush Street). The traffic was classic Chicago, start and stop. It was a beautiful day, but when I got to Lincoln Park my controller was feeling hot and starting to smell a little. I should have sprayed it down with water or took an hour break to cool it off. I should have taken a detour on the way back. But the start and stop traffic was too much for it. By the time I got back my starting point my controller was super hot and smelling very fried. I knew I had probably ruined my controller and was feeling a little stupid, because while I had enjoyed the ride, I could have completed my trip in less time on a bicycle with the same or better experiences along the way. July 2009 Note: A contributing factor to this failure was probably my turning the controller on and off at street lights trying to save power and cool the controller down. I believe now, that I was probably shocking the capacitors in the controller by not letting the precharge resistors do their job in addition to having poor heat sinking... On Sept. 3, I took it for a 18 mile ride and it seemed to work just fine. On Sept. 8, I went out to go for a ride, turned on the power and got SNAP, CRACKLE, POP, SMOKE, SPARKS coming out of all openings of controller. I was really glad I had a Battery Disconnect Switch hooked up! And I was thankful it happened in my garage, not in the middle of a ride or in downtown Chicago (how embarrassing)! September 18, 2007: NEW CONTROLLER PURCHASED ON E-Bay Installed and working. I purchased a Curtis 1204-410 Motor Controller on E-Bay for $125! I got it and hooked it up just like my Altrax but it did not work. I tried all kinds of things, but it just seemed dead. I downloaded the User Manual from Curtis Instruments website (it contains some really great information that the Altrax manual did not). From the manual, I could see that I needed to learn how my controller was configured at the factory, so, I e-mailed Curtis Instruments with my serial number and they responded with the following: Hello Kraig, This is an exclusive controller for Club Car. It uses a 3-wire 5K pot. The wiper and one end of the pot is connected to the controller. The second end is tied to B-. It has no HPD and the current limit is reduced to 225Amps (The 1204-4xx series is normally set to 275 Amps.) So I purchased a 5K pot at Radio Shack and hooked it up as instructed and the controller worked! Then, I took my Magnura twist grip throttle apart (don't do this, it's really hard to get it back together!) to see if I could swap out the Potentiometer in it only to find out that the Magnura IS a three wire potentiometer! The Blue wire had been snipped so that I couldn't tell without opening it up! The black and brown wire give 0-5K and the blue and brown wires give 5K-0 operation. |

The wiring diagram above shows how to hook up a 3 wire pot to a Club Car Controller. Note: THIS IS NOT THE WIRING DIAGRAM FOR MY MOTORCYCLE. The throttle response override resister should be placed in parallel with the 0-5K legs of the potentiometer for this controller. This controller has thermal disable features that should make it better than the Altrax. I'm interested to see how its performance varies from the Altrax. Note on 10-18-08: Curtis controller has went 1,500 trouble-free miles and seems to give better max speed than Altrax and it looks a lot better on the bike (with a nice silver color verses the bright blue and white Altrax color scheme). |

|

September 26, 2007: NEW MAX SPEED 53 miles per hour! w/ 225 amp Curtis Controller, 17:42 gear ratio.

|

|

September 29, 2007: Cleaned up my controller installation and added an aluminum finned heat sink underneath to avoid heat problems that ruined the Altrax controller.

|

|

October 11, 2007: 30 to 42 Gear Ratio Test

I had a theory I might be able to exceed 65 mph with better gearing. So I installed a 30 tooth sprocket on my motor with the stock 40 tooth rear sprocket. The result was terrible acceleration, hot smelling controller and motor and a max speed of only 45 mph.

|

THE EV GRIN: I wish I'd taken a picture or video everytime I let someone ride the E-Bike the first time. They come rolling back in with this huge grin, and they are saying something like, 'Dang, this thing is impressive. It has way more torque/power/speed than I expected. And it's so quiet!' After I get the rider prepped with a helmet and familiar with the controls, it's not unusal for them to take off and totally disappear for a few minutes. After awhile, I start thinking, 'Maybe I shouldn't let just anybody ride this thing. What if something went wrong and he gets hurt on it?' Then, I'll see them coming back down the road, and I release a sigh of relief. But, then instead of stopping, they sometimes go whizzing by and disappear in the other direction! |

NEW FAIRING:

10-21-07 Max speed with new fairing: 57mph!!! The name on fairing is "Tracy". I bought it from a Marvyn at his motorcycle junk yard in Scottsville, MI (231-757-3944). |

|

10-24-2007 CHARGER DIED TODAY: My cheap Chinese Charger went bad today. I took it apart and found it had a fuse to protect itself. I replaced the fuse and several components emitted smoke when I plugged it in. So, I went shopping on the internet and hoped to get a Soneil 4820SR at a decent price, but instead went with the Zivan NG1 Multistage for improved performance/value. Also, I was impressed that some major manufacturers include them in their premium packages (i.e. Myers Motors puts them in their Sparrow). I was concerned about the fast charging rate (18amps at 48volts), but was told that my AGM batteries should like it. So, I should see recharge times almost 4 times as fast as my old charger. This means I'll should be able to get more riding in on nice days! The Zivan charger must be programmed at the factory so the lead-time is longer than for an off-the-self application. The programming includes input voltage (110 or 220vac), pack voltage, number of cells, and amp-hours of batteries. Not having a spare charger meant I spent a lot of time carefully charging my batteries with my 12 volt car charger. I had to be careful to not over-charge the batteries as sealed lead acid batteries will vent (loose water) if over charged and since water cannot be replaced this will shorten their life. I'm thinking having a back-up trickle charger would be nice in case my primary charger goes bad. Or, at a minimum, I should buy a timer that will automatically turn my car charger off after a set time. |

|

12-14-2007 ZIVAN CHARGER FINALLY ARRIVED

In the mean time, I purchased a timer to put on my 12V car battery charger to help not over charge my batteries and eventually (over Thanksgiving weekend) ordered a cheap chinese 48V charger off E-bay. The E-bay charger arrived in less than a week. So, now I have three ways to charge the batteries... I decided to mount the cheap charger on the bike (it is lighter, and smaller than the Zivan) as the chargers are not waterproof and vibration is not good for them. Better to fry a $50 charger than a $500 charger. This works good in practice, because I have plenty of time to recharge at work with the slower on-board charger, and I have my fast charger for at home where I generally want to go for several rides per day on evenings/weekends with faster charges available. |

|

4-24-08 ZIVAN CHARGER PERFORMANCE

From drained condition 95% Depth of Discharge = 28 miles at 28mph. I recharged my battery to 80% in 2:40 hours with the Zivan NG-1 Charger. Nearly 100% charged 7 hours later. click here to see data |

|

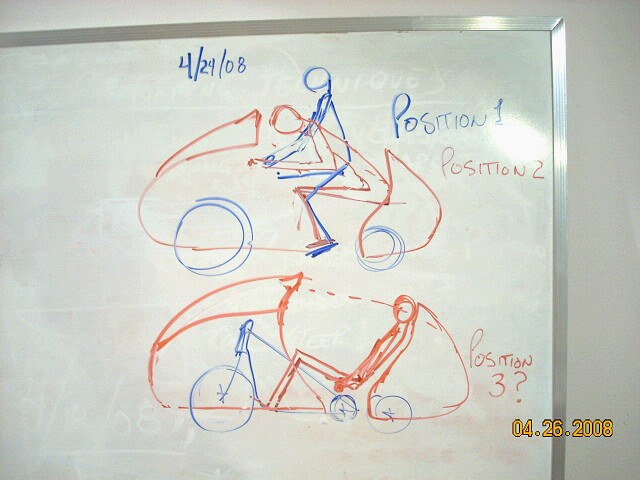

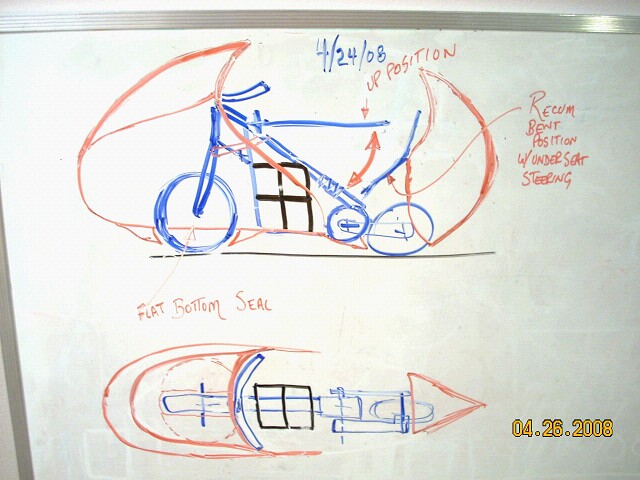

4-26-08 DUSTBIN FAIRINGS CONCEPTS FOR THE BIKE

Here are some concepts for fairing to build for the bike:

|

|

THROTTLE LOCK:

Instead of messing with the butt switch, I added a throttle lock to save my wrist on long rides and provide for fine control over cruising speed. Here is a Quicktime video of it in action. I can lock the throttle on the handlebars and adjust my cruising speed via the throttle response potentiometer. I machined a little piece of aluminum to form a pivoting trigger lock. It attaches to the Magnura twist throttle with a little piece of stamped metal. Foam rubber is the return spring (black electrical tape is wrapped around the foam in the pictures below). The lock engages a notched collar. The notched collar is a snug fit on the Magnura throttle, so it acts as a clutch and the lock position can be moved or overridden by twisting the throttle with more force. Picture of throttle not locked.  Picture of throttle in locked position.   |

|

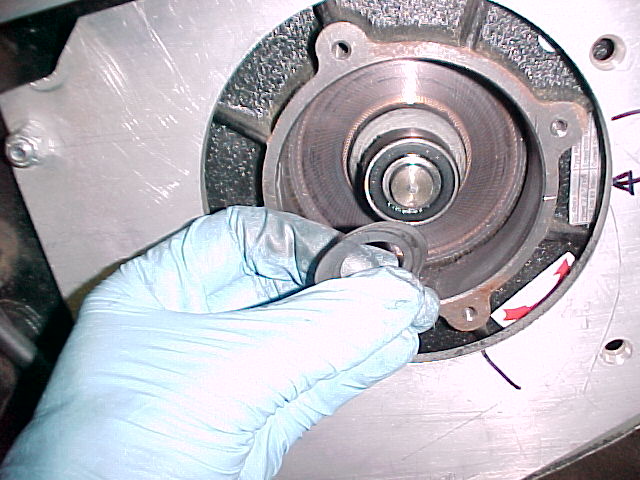

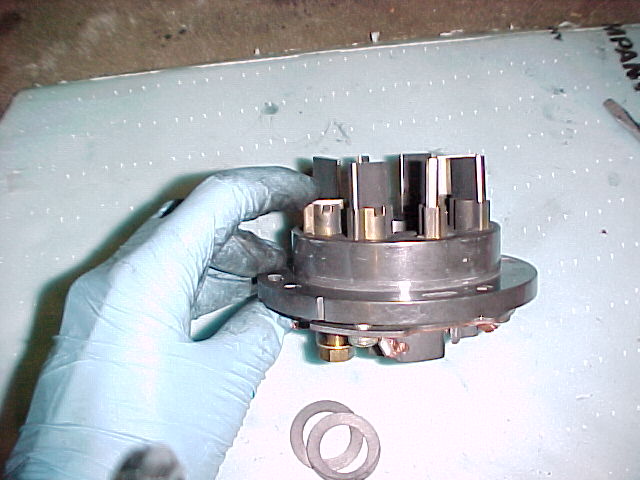

July 12, 2008 PERM-132 BRUSH LIFE WHEN RUNNING CCW

I asked the PERM manufacturer the following questions:Today, I removed the brushes from the Perm-132 motor to inspect them for wear. One end of the armature is supported by the brush assembly. The outer race of a sealed bearing (PN 6202 RSR) is a slip fit into the brush assembly. The bearing will stay on the armature shaft when the brush assembly is removed. The brush assembly is held in place by four, 5mm allen head cap screws. Once the screws are removed the brush assembly can be pulled out. Since the bearing on this end of the motor is supported by the brush assembly, wiggling the output shaft of the motor helps get the weight of the armature off the brush assembly (I used an eight inch long, 7/8" I.D. piece of conduit to give me leverage on the output shaft) so that the brush assembly can be gently pulled out.  One set of bellvelle spring washers will fall out when the brush assembly is removed. The bellvelle washers belong in between the bearing and the brush assembly when putting it back together.  The picture below shows the brush assembly with one of the brushes being depressed by my finger.  If the brush assembly is taken farther apart, the brushes can be measured as shown. Don't do this unless you are replacing the brushes. It is a pain in the butt getting the springs to go back into the assembly...  The motor has 1,150 miles on it at Moped speeds (Estimated Average speed for 1,150 miles is 27 mph). I estimate I average about 20 amps while cruising at 28 miles/hour. The brushes now measure about 15/16" (24mm) long. I am using your PMG-132 motor in an electric motorcycle. What Preventative maintenance is recommended? What is estimated brush life? Do you have instructions for replacement of brushes? Do you sell replacement brushes? They answered: +check brushes that they move perfect in the slides. +brushlife depends on Voltage turning direction and currents you are giving through the controller, so there is no answer I can give you without knowing more on the system. +for example 48 V CL turning direction continous current between 50 and 100 A , 2000 to 3500 hours. but this can go down rapidly with changing parameters. +normally we sell only complete brushholders as replacement. if you like only the brushes we could also do but there is no instruction for that. |

|

INSURANCE ISSUES - Moped Vs. Motorcycle

I recently purchased insurance for my moped. In Michigan insurance is not required for a moped, however, I found out that my medical insurance doesn't cover me should I be involved in an accident with my moped. So, I decided it was worth it. So, now the advantages of registering as a Moped are waning. In theory, registering as a moped is better than a motorcycle because no helmut is required, no insurance is required, yearly registration is much less ($15 per 3 years instead of $45 per year). However, I always wear a helmut, I had to purchase motorcycle insurance anyway. Also, I'd like to carry a passenger (passengers are illegal on mopeds in Michigan), and I'd like to go faster than 30 miles per hour sometimes. |

|

(Next Chapter - Dreams out of the Dustbin) |

|

This webpage was written by Kraig D. Schultz. Copyright 2007-2010, Schultz Engineering, LLC |